- +86 19149417743

- Zhengzhou, Henan Province, China

- Mon-fri: 8am - 7pm

Get a quote

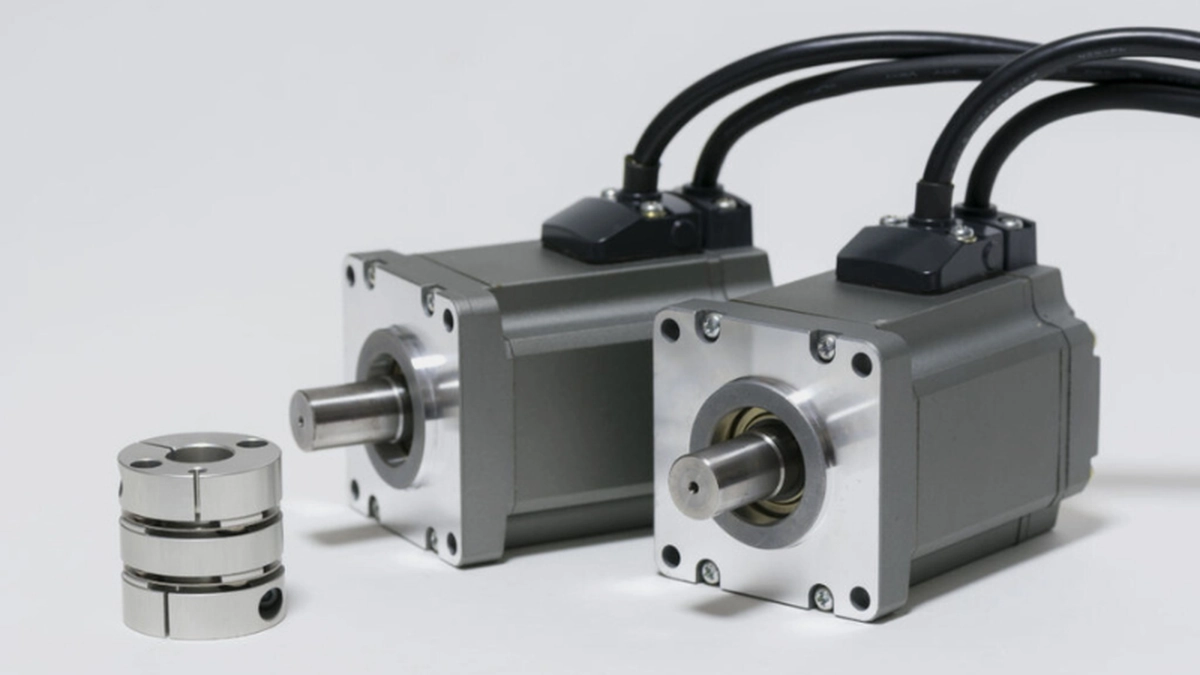

Servo motors are divided into two main categories: AC servo and DC servo.The basic structure of AC servo motor is similar to that of AC induction motor (asynchronous motor). There are two excitation windings and control windings on the stator with a 90° electrical angle displacement. By applying a constant AC voltage to the excitation windings or changing the phase of the voltage, the purpose of controlling the motor operation is achieved. AC servo motors have characteristics such as stable operation, good controllability, fast response, high sensitivity, and strict nonlinearity index requirements for mechanical and adjustment characteristics (less than 10% to 15% and less than 15% to 25% respectively).

The basic structure of a DC servo motor is similar to that of a general DC motor. The motor speed is given by n=E/K1j=(Ua-IaRa)/K1j, where E is the armature back electromotive force, K is a constant, j is the number of poles, Ua and Ia are the armature voltage and current, and Ra is the armature resistance. By changing Ua or φ, the speed of the DC servo motor can be controlled. However, the method commonly used is to control the armature voltage. In a permanent magnet DC servo motor, the excitation winding is replaced by permanent magnets, resulting in a constant magnetic flux φ. DC servo motors have good linear adjustment characteristics and fast time response.

DC servo motors are divided into brushed and brushless motors. Brushed motors have low cost, simple structure, high starting torque, wide speed range, easy control, and only need to replace the brushes regularly. However, they may generate electromagnetic interference, have requirements for the operating environment, and are usually used in cost-sensitive general industrial and civilian applications. Brushless motors are small in size and light in weight, with high output, fast response, high speed, small inertia, stable torque, smooth rotation, complex control, intelligent, flexible electronic commutation, can commutate with square wave or sine wave, maintenance-free, efficient and energy-saving, low electromagnetic radiation, low temperature rise, long life, suitable for various environments.

Servo motors for communication are also brushless motors, divided into synchronous and asynchronous motors. Currently, synchronous motors are generally used in motion control, with a wide power range. The power can be very large, with a large inertia, low maximum speed, and the speed decreases uniformly as the power increases, suitable for low-speed stable operation. The rotor inside the servo motor is a permanent magnet. The driver controls the U/V/W three-phase electricity to form an electromagnetic field, causing the rotor to rotate under the action of this magnetic field. At the same time, the motor's built-in encoder feeds back signals to the driver, comparing the feedback value with the target value to adjust the angle of rotation of the rotor. The accuracy of the servo motor depends on the accuracy (number of lines) of the encoder.

2024-08-30 16:01:40

Engineering

2024-08-30 16:01:40

Engineering

2024-07-26 14:09:13

Engineering

2024-07-26 14:09:13

Engineering

2024-07-18 09:42:00

Engineering

2024-07-18 09:42:00

Engineering