Common fault analysis and solutions of engraving machines

The engraving machine is a relatively basic type of CNC machine tool and is a commonly encountered equipment in production and life. It is usually used to process non-metallic materials, which are divided into X-axis, Y-axis and Z-axis. The following provides some solutions to the following common faults that are often encountered:

When the button moves, the axis only moves in one direction.

- Check whether the optical coupling line is working properly and whether the circuit is in good contact.

- Check whether there is any weak welding on the motor circuit.

The sending software cannot be opened normally, and the engraving appears deformed.

- Reinstall the new system and software.

- Check whether the X, Y axis lead screws and screws are loose.

- There is a problem with the engraving tool.

Signal cannot be transmitted

- Are the engraving machine parameters and computer settings correct?

- Whether the signal cable is connected correctly.

The engraving material is unclean

- The tool is dull, has some wear and needs to be sharpened.

- Whether the tool settings in the software match the actual tool used.

- Whether to add lubricant when engraving hard materials (such as metal, jade, glass, etc.).

- Whether the tool holder is concentric.

The machine head cannot be returned to the zero position and the engraving machine format is reduced or out of bounds.

- If the machine head cannot be returned to the zero position, the screw may be misaligned and the screw needs to be adjusted.

- The travel switch is damaged.

- If the machine head cannot return to the zero position and the engraving machine format is reduced or out of bounds, it may be that the "model" in the machine settings does not match the actual model.

Running knife

- If the ground wire is not installed, static electricity will occur, causing tool running and misalignment.

- The printer parameters in the software do not match the printing parameters of the engraving machine.

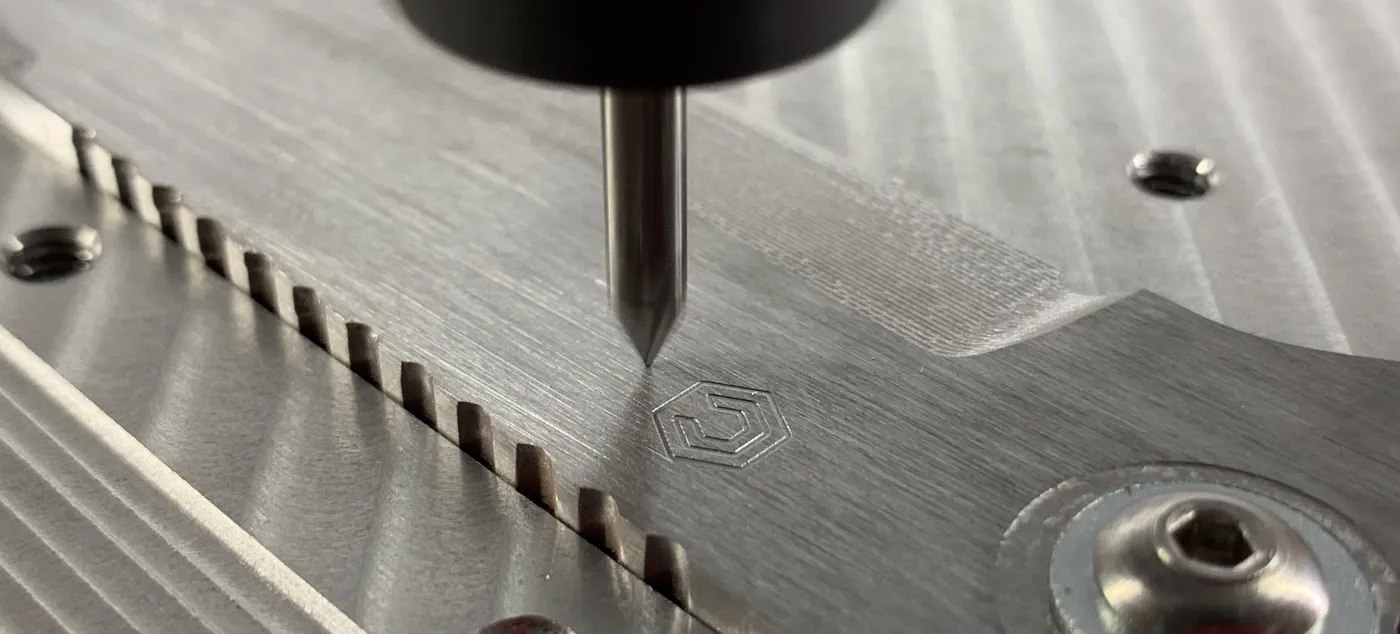

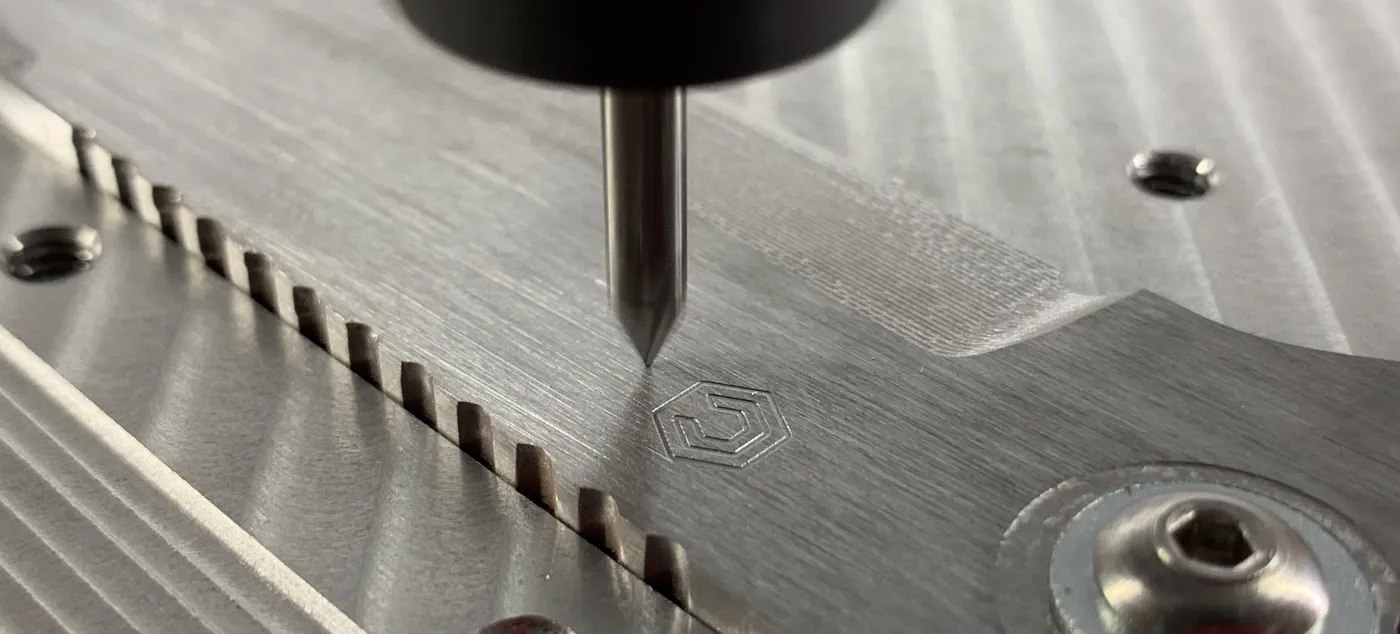

The knife often breaks when engraving hard materials

- When engraving hard materials, you need to set different engraving parameters and use different tools according to different materials.

- Select the appropriate lubricant.

Select the appropriate lubricant.

- If the ejector rod cannot reach the limit switch, just correct it.

- The drive wire is not in good contact. Try to fix the drive wire firmly.

- The limit switch wire is not connected properly. Just connect the wire well.

- The limit switch is broken, just replace it.

The engraving machine cannot engrave at the origin

- Whether the layout size of the file matches the machine.

- Check whether there is an offset (OFFSET) and whether the layout setting is correct.

The spindle motor suddenly stops or rotates slowly during the operation of the engraving machine.

- If the working voltage is unstable or overloaded, just add a voltage stabilizer.

- Check whether the middle wire is connected well and whether the wire ends are desoldered.

When setting the origin of the engraving machine, it sometimes deviates forward or to the right by an uncertain distance.

- The limit switch fails. When the system returns to the system origin, the limit switch first closes and then pops open. Just replace the limit switch.

- If the drive wire is loose, try to fix it tightly.

When the engraving machine is started and reset, the X-axis, Y-axis, and Z-axis positions are uncertain.

- The limit switch is broken (the limit switch is always closed), just replace it.

- The drive wire is broken (pins 14 and 15 of the X-axis are short-circuited, pins 13 and 15 of the Y-axis are short-circuited, pins 31 and 15 of the Z-axis are short-circuited), just change the drive wire or separate the short circuit.

- The driver board is broken, just replace the driver board.

The engraving machine cannot engrave at the origin

- Whether the layout size of the file matches the machine.

- Check whether there is an offset (OFFSET) and whether the layout setting is correct.

The spindle motor suddenly stops or rotates slowly during the operation of the engraving machine.

- If the working voltage is unstable or overloaded, just add a voltage regulator.

- Check whether the intermediate wire is connected properly and whether the wire ends are desoldered.

The engraving machine beeps when it is started and reset, or the limit switch is always good or bad.

- If the ejector rod cannot reach the limit switch, just correct it.

- The drive wire is not in good contact. Try to fix the drive wire firmly.

- The limit switch wire is not connected properly. Just connect the wire well.

- The limit switch is broken, just replace it.

2024-08-30 16:01:40

Engineering

2024-08-30 16:01:40

Engineering

2024-07-26 14:09:13

Engineering

2024-07-26 14:09:13

Engineering

2024-07-18 09:42:00

Engineering

2024-07-18 09:42:00

Engineering