- +86 19149417743

- Zhengzhou, Henan Province, China

- Mon-fri: 8am - 7pm

Get a quote

AC (alternating current) and DC (direct current) motors are vital components in various industrial, commercial, and residential applications. Starting these motors correctly is crucial to ensure their reliable operation and prevent any damage. In this article, we will explore the different methods and techniques for starting both AC and DC motors, providing a detailed understanding of the starting process for each type.

AC motors are the most widely used motors in the world due to their robustness and simplicity. Starting an AC motor is relatively straightforward, but this can vary significantly depending on the motor type.

Synchronous motors require synchronization with the power source's frequency to operate effectively.

For smaller synchronous motors, a Direct On-Line starter can be used where, upon activation, the full line voltage is applied to the motor. This method is efficient but can lead to high inrush currents.

A VFD controls the frequency of the electrical power supplied to the motor, allowing for a gradual increase to the desired operating speed. VFDs are ideal for processes that require speed control and aim to reduce energy consumption.

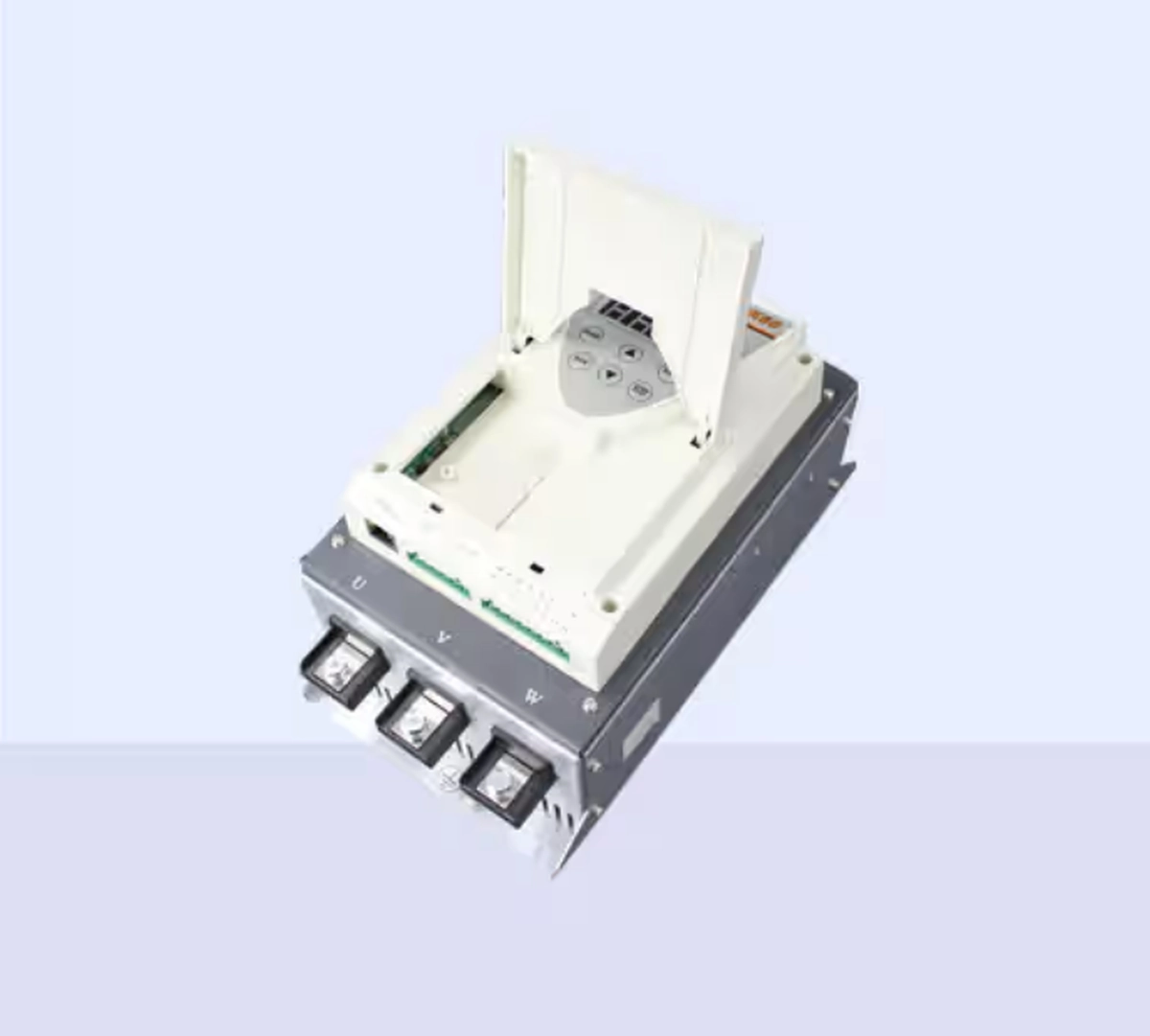

Soft starters temporarily reduce the load and torque in the power train and the electric current surge of the motor during startup. They employ a series of controlled voltage ramp-up sequences to gently start the motor.

Induction motors are more common than synchronous motors and have different starting requirements due to their asynchronous nature and the need for an induced rotating magnetic field to create torque.

The Star-Delta starter method involves starting the motor in a 'star' configuration and then transitioning to a 'delta' configuration, which lowers the voltage during startup to minimize mechanical and electrical stresses.

With this method, the motor starts with reduced voltage, using an autotransformer to decrease the inrush current and increase the voltage until the motor reaches operation speed.

DC motors are popular for their ease of speed control and high starting torque, making them preferable in devices such as electric vehicles.

Just like their AC counterparts, smaller DC motors can be started with a basic Direct On-Line starter, applying the full voltage across the armature. A protective device might be used to limit the initial current.

For larger DC motors, series resistors could be introduced into the armature circuit to control the starting current. As the motor speeds up, the resistors are gradually shorted until the motor reaches full operational velocity.

These devices adjust the motor's voltage by phase angle control. They are particularly useful for smooth starting and speed regulation in DC motors and offer an efficient technique for controlling the power that's delivered to the motor.

Sophisticated DC motor starters may be equipped with starting current limiters, which ensure that the current does not exceed a predefined level.

During motor starting, both AC and DC motors experience a high inrush current, which can be several times higher than the motor's rated current. This initial surge of current must be considered when sizing the power supply and selecting protective devices such as circuit breakers and fuses.

The starting torque requirement varies depending on the application. It is essential to ensure that the motor's starting torque is sufficient to overcome the load's inertia and any static or dynamic resistance during the starting phase.

To protect motors during the starting process, various protective devices are employed, such as overload relays, thermal protection devices, and motor starters. These devices monitor the motor's current and temperature, providing protection against excessive currents or overheating.

Starting an AC or DC motor involves complex electrical and mechanical processes tailored to safeguard the motors' life and ensure maximum efficiency. The selection of the method heavily depends on the motor's size, type, and application.

2024-08-30 16:01:40

Engineering

2024-08-30 16:01:40

Engineering

2024-07-26 14:09:13

Engineering

2024-07-26 14:09:13

Engineering

2024-07-18 09:42:00

Engineering

2024-07-18 09:42:00

Engineering