- +86 19149417743

- Zhengzhou, Henan Province, China

- Mon-fri: 8am - 7pm

Get a quote

In the realm of electrical engineering, the choice between alternating current (AC) and direct current (DC) motors is a crucial decision. AC motors, in particular, have gained widespread popularity due to their numerous advantages in various applications. In this article, we will delve into the specific advantages that AC motors offer over their DC counterparts, shedding light on why they are preferred in many industrial and commercial settings.

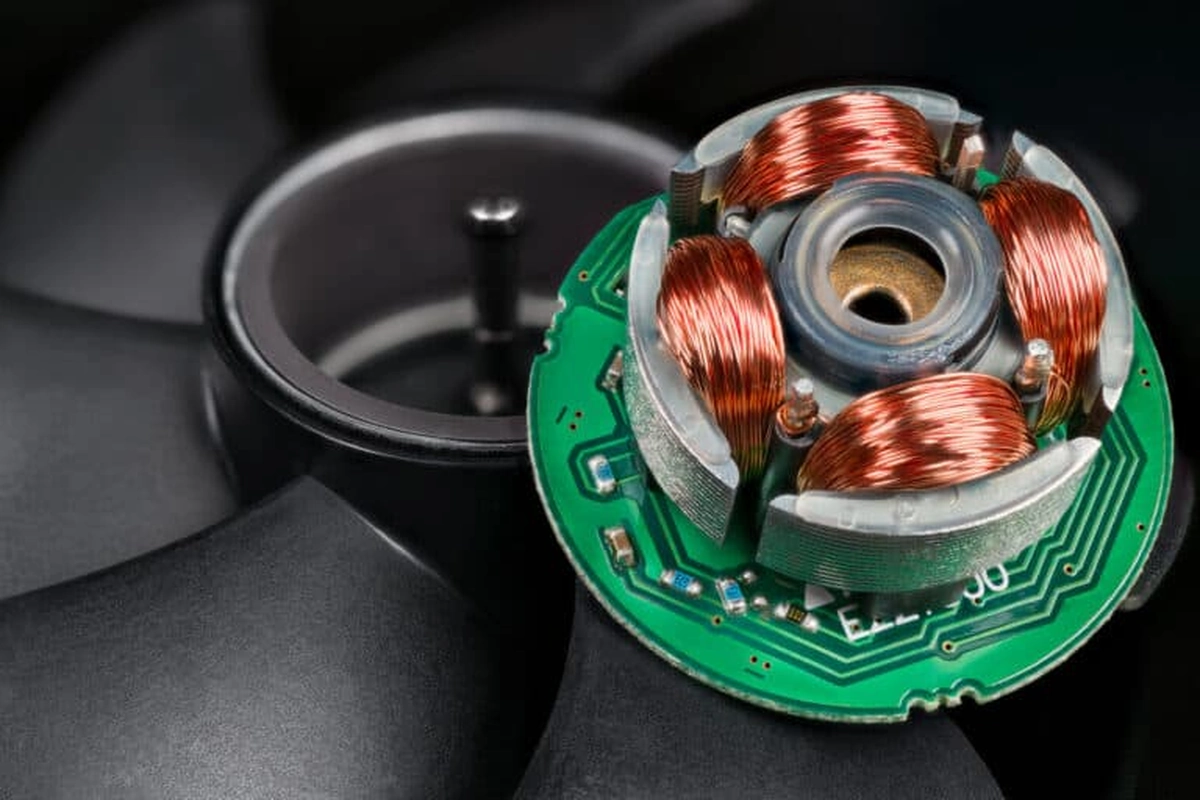

Before delving into the advantages of AC motors, it is essential to understand the basics of how they operate. AC motors function by converting electrical energy into mechanical energy through the use of alternating current. The most common types of AC motors include induction motors and synchronous motors, each with its unique characteristics and applications.

AC motors are known for their relatively simple construction compared to DC motors. This simplicity translates into lower manufacturing costs, making AC motors a cost-effective solution for various applications. The straightforward design of AC motors also results in easier maintenance and repair procedures, reducing downtime and overall operational costs.

AC motors offer a broad range of speed and torque capabilities, making them versatile in different applications. By adjusting the frequency of the electrical supply, AC motors can achieve varying speeds and torque outputs, catering to the specific requirements of the machinery they power. This flexibility is particularly advantageous in industrial settings where different loads and operating conditions are common.

One of the key advantages of AC motors is their superior energy efficiency compared to DC motors. AC motors operate at higher efficiency levels, converting a greater percentage of electrical energy into mechanical work. This efficiency not only reduces energy consumption but also leads to cost savings over the long term, especially in applications where motors run continuously.

AC motors are renowned for their robust and reliable performance in diverse operating conditions. The design simplicity of AC motors contributes to their durability and ability to withstand harsh environments. This reliability is essential in critical applications where downtime can lead to significant production losses or safety risks.

AC motors are highly scalable and compatible with various control systems, making them adaptable to different industrial processes. From small fractional horsepower motors to large high-power motors, AC motor technology can be tailored to meet specific power requirements. Furthermore, the compatibility of AC motors with modern control systems enhances their integration into automated processes, optimizing efficiency and productivity.

In conclusion, the advantages of AC motors make them a preferred choice for a wide range of industrial and commercial applications. Their simplicity, cost-effectiveness, wide speed and torque range, energy efficiency, reliability, scalability, and compatibility contribute to their widespread adoption in diverse sectors. As technology continues to advance, AC motors are poised to play a pivotal role in driving innovation and enhancing operational efficiency across various industries.

2024-08-30 16:01:40

Engineering

2024-08-30 16:01:40

Engineering

2024-07-26 14:09:13

Engineering

2024-07-26 14:09:13

Engineering

2024-07-18 09:42:00

Engineering

2024-07-18 09:42:00

Engineering